True sustainability must be 'circular'

/Building the circular economy

We are very familiar with living in a linear economy, where we take, make, consume and finally dispose. At every stage of this process we are eating into more and more precious natural resources with little regard for the impacts.

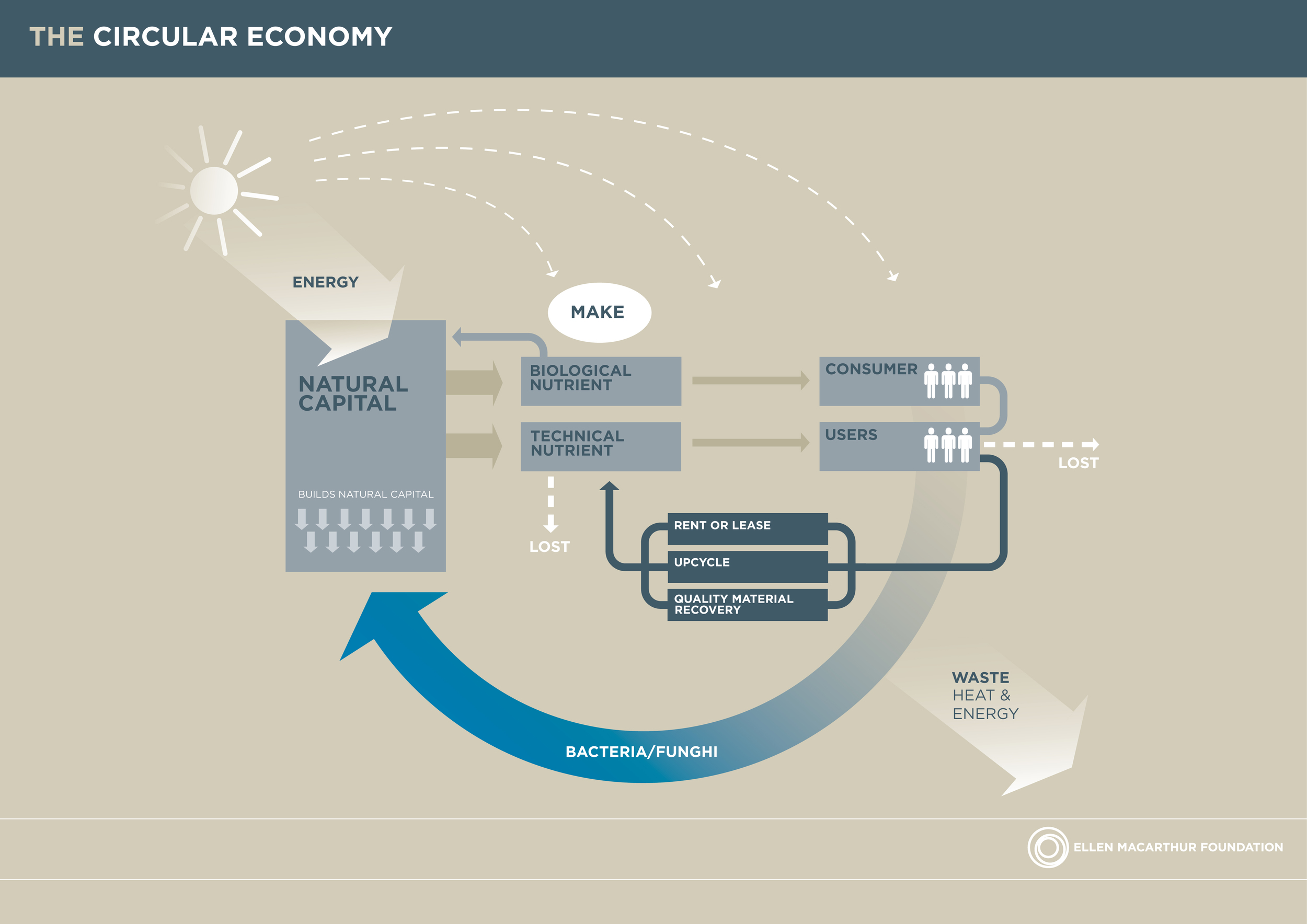

The circular economy refers to an industrial economy that is restorative: it aims to rely on renewable energy and hopefully eradicates waste through careful design and discussion.

The creation of the Ellen MacArthur Foundation in 2010 looked to challenge the linear economy and move us towards a more circular economy.

Let me explain …

That shiny new car you just bought is in fact a reincarnation of an older vehicle – stripped back and recycled.

In 2000 the EU brought in the ‘End of Life Vehicles Directive’ stating that it is the manufacturer’s responsibility to build cars that can be broken down when they become no longer serviceable.

With ever diminishing world resources, a hike in material costs and a global increase in environmental responsibility, car manufacturers are increasingly turning to recycled materials to create various elements of their new dream machines.

Did you know that when buying a new Volkswagen Golf the wheel housing liner is made from 100% recycled polypropylene and 80% of the gearbox is made from recycled materials?

This is a great step towards making our cars that little bit more sustainable.

Could we do the same for buildings?

As architects, should it become our responsibility to think about an ‘end of life’ building strategy? And if so, how would the construction industry cope with such legislation?

Small changes to the way we design buildings now, like those changes made within the automotive industry, will help later when buildings are broken down and recycled. The materials we specify for construction or finish can be made from recycled material with the ability to be recycled again. This all feeds into a circular cycle.

When designing buildings we can look to use ‘off the shelf’ construction elements and readily available industry standard size products which can be easily reused on future builds.

At SRA we don’t claim to have all of the answers yet, but we are actively inviting the discussion and looking for like-minded people to work with. Let’s make buildings that can be made again . . . and again.

We welcome your thoughts on the matter.